Silicone rubber products Production Process

Silicone rubber products are not only seen everywhere in our life, but also widely used in industrial fields, and different fields have different requirements for silicone rubber products. The common silicone rubber products in our life are silicone protective covers, silicone kitchenware, tableware, silicone household products, silicone molds, etc. So, how are they produced? Here is a brief introduction to the production process of silicone rubber products.

The first “material selection” according to the use of the production environment and quality requirements, select the appropriate silicone rubber materials, such as product wear resistance, oil resistance, acid resistance, alkali resistance, high and low-temperature resistance, tensile strength and so on these requirements, and to determine the choice of which material is more reasonable.

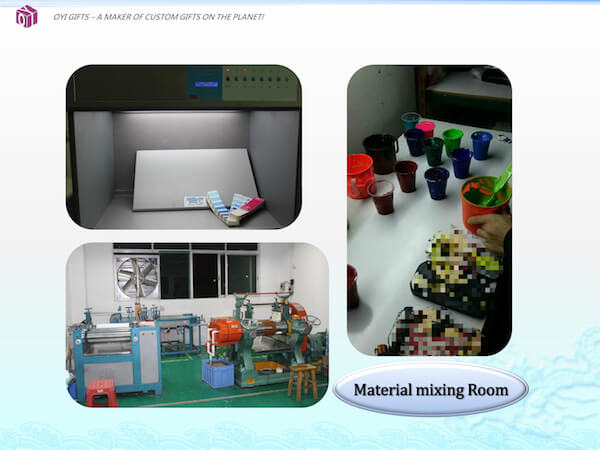

The second “refining” many times we purchase back the raw material is still only raw rubber, and can not be used directly in production, but also need to carry out secondary processing, we call it refining, refining is also in the raw rubber inside a certain proportion to add accelerators, color powder and other auxiliary molding ingredients to meet production requirements.

The third “cutting” is to get a whole piece of material after refining, and then we need to cut the whole piece of material into the final weight, shape, and size that we need according to the structure and size of the product.

The fourth “molding” after the completion of the above work is to carry out the most important step is molding, we have to cut the material in the previous step into the silicone rubber mold, according to the predetermined process parameters for hot pressing, and finally get our desired size, of course, there is no hot pressing, but directly through the injection molding machine, the material into the mold cavity and get Of course, there is no hot pressing, but directly through the injection molding machine, the material into the mold cavity and get the required products, this is similar to the principle of the syringe.

The fifth “processing/inspection” molding is a block of products, we also need to separate the part of the product from the middle, and then remove the product edges, the product appearance inspection, so a qualified silicone rubber products will be completed its entire process.

Of course, the above does not mean that all silicone rubber products’ production process is like this, or according to the actual situation and the customer’s quality requirements for the product to determine. In addition, it should be noted that in the solid state molding process, the silicone products manufacturer’s molding process is currently the most extensive one, and its core problem lies in the upper and lower mold parting lines.

For the appearance of more stringent products, the size of the fractal line determines the grade of the product, so for the mold, in the molding process, the biggest problem of many silicone daily necessities is in the fractal line, and the main way to solve it still lies in the production source, the production of the mold and the quality control of the silicone processing factory production staff. Therefore, we want to solve this problem from the source, we need to pay attention to the choice of quality manufacturers when customizing silicone rubber products. Quality manufacturers are experienced in R&D, mold making, customization, and production, with relevant certifications, from raw material incoming inspection to made inspection, finished product inspection, shipping inspection, and strict control of quality standards, so as to protect the quality of products.

If you are interested in customized silicone products, welcome to contact us directly, thanks in advance!