What is the production process of silicone products, silicone products sample mold production requirements

The production process of silicone products is complicated, and each kind of silicone product needs to have a mold before production, the technical requirements of mold making are relatively high, and if the quality of silicone molds is not good, then the impact on the production of silicone products is relatively large. So what are the requirements of silicone products sample mold making? The following OYIGIFTS tell you.

The sample mold is usually open 1 hole to 2 holes, when the sample wants more, our sample mold will also open 4 holes. The sample mold plays the role of confirming the first sample, it turns the drawing into the real thing. Because silicone is flexible, the actual product may not match the drawing, so we can only open a sample mold first and let the customer confirm the sample. If there is a problem with the sample mold, it is easier to modify the mold at this time, and the modification time is short and efficient. Every time we open a mold, we have to confirm the product by making a sample, that is to say, we have to confirm the mold. When the product is developed to meet the requirements of the customer, the mold is confirmed.

The raw material of the sample mold

Our sample molds are made of steel. The size of the mold is determined by the size of the product. Usually, we use a 300mm*300mm*30mm long*width*height template.

Production time of sample mold

The production time of the prototype is determined by the complexity of the product structure. Usually, it takes about 2-3 days from programming to processing for simple products and 5-7 days for complex ones. The more complex the product structure, the longer it takes to open the mold.

The advantages of sample mold opening

First of all, the number of cavities opened in the sample mold is small, the use of the template is small, the processing time is short, so the cost is smaller and the efficiency is high. Secondly, there are some other benefits of opening sample mold, such as even if the product structure is not confirmed, it is easier to modify the mold, and the modification can be confirmed by proofing immediately after the modification so that the time is shortened. Third, because of the low cost, first opening the sample mold can reduce the risk. If you directly open a large mold, the second and can not confirm the sample, with the modified mold when producing products will bring a lot of quality problems, the mold, in this case, will only be repaired worse, the more repair is not conducive to production. So opening a sample mold can achieve the purpose of first confirming the product, confirming that there is no problem, then opening the large mold at once so that the production of the product will rarely have quality problems.

The difference between sample mold and mass production.

Sample molds and mass production molds compared to a lot smaller, but the structure, material, the production process is the same, a new product comes out, and all need market superiority and inferiority. Sample mold is to reduce the initial market investment. More effective feedback on the market positioning of the project, for the later batch production, to accumulate data or to obtain more market information. Sample molds are effective for some products and can be confirmed in structure according to this traditional way.

To sum up, when making sample molds for silicone products, there are relatively high requirements for the raw materials and production time of sample molds, and it is necessary to follow the relevant regulations in order to do a good job of making sample molds for silicone products.

What are the characteristics of silicone products?

Speaking of silicone products, we are certainly not unfamiliar, after all, these silicone products can be seen everywhere in our schedule life, as small as our common electronic products protective cover, such as cell phone silicone protective cover, Bluetooth speaker protective cover, etc., to the car engine system rubber intake tube, wire harness sheath, etc., it can be said that silicone rubber products have penetrated into our lives in every drop. So what is the production process of silicone rubber products, today we talk to you about the production process of our silicone products.

First, Silicone material characteristics

A. Silicone raw materials are generally gel-like, somewhat similar to play-doh, colorless and translucent, and tasteless.

B. Its main feature is both high-temperature resistance (up to 300℃) and low-temperature resistance (minimum -100℃), which is the best cold and high-temperature resistant rubber at present; meanwhile, it has excellent electrical insulation, high stability to thermal oxidation and ozone, and is chemically inert. The disadvantage is that the mechanical strength is low, oil resistance, solvent resistance, and acid and alkali resistance are poor, more difficult to vulcanize, and the price is more expensive. Use temperature: -60℃~+200℃. The above is the description of silicone rubber in the manual.

C. Use temperature: as described above, generally set to -40℃ – 200℃, and up to 230℃ in a short time role.

D. Aging problem.

Oil resistance, acid, and alkali resistance are poor, and not much related to the force situation.

E. bonding problems: before the surface treatment, in addition to silicone products for adhesives and silicone parts bonding, and other parts sticky all must be activated by the surface, rubber surface vulcanization treatment to sticky. Where the rubber can be vulcanized or cross-linked substances are collectively referred to as vulcanizing agents, also known as cross-linking agents. Many types of vulcanizing agents, and is still increasing, have been used vulcanizing agents are sulfur yellow, selenium, tellurium, sulfur-containing compounds, metal oxides, peroxides, tree esters, quinones, amines, etc.

F. Material hardness: rubber parts by Shore hardness in the domestic market can theoretically choose between 10 degrees to 80 degrees. Can be easily found in general in 20 degrees to 70 degrees, the most commonly used is 40 to 50 degrees.

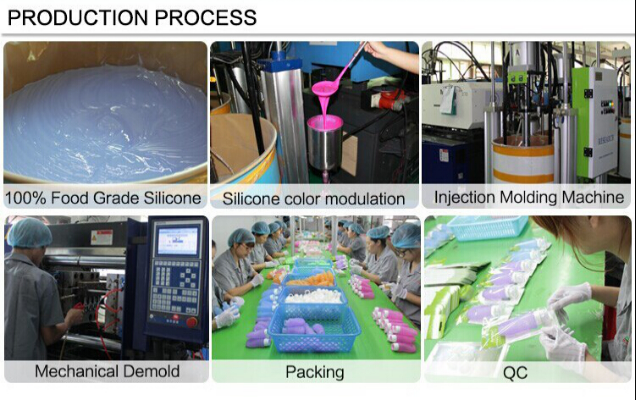

Second, the production process of silicone products

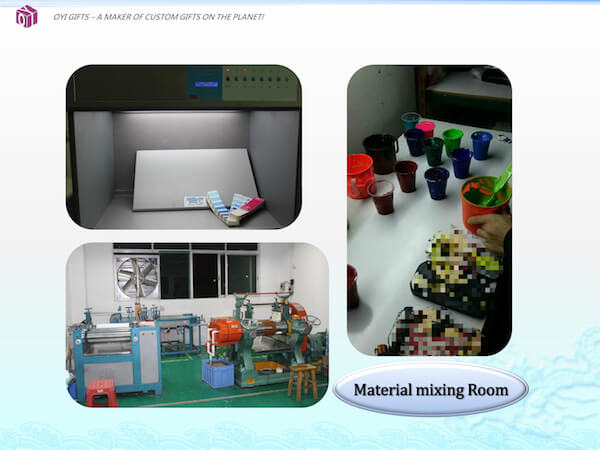

A Raw material shape and color

B After color-matching and mixing, it is transformed from milky white silicone into various colors of sheet material C After mixing and shaping, the raw materials are pressed into strips and cut into a strip of material.

D vulcanization molding

E trimming, edge removal, inspection, packaging.

F.Finished product picture

What is the use of silicone products?

Want to know what is the use of silicone products? With the development of the silicone industry all over the world, there are silicone products everywhere, such as the most common silicone keys, silicone phone cases, etc. When we use a calculator, we find that the keys are very flexible, flexible, and comfortable to touch. Silicone has an open porous structure and can adsorb many substances, making it a good desiccant, adsorbent, and catalyst carrier. The adsorption effect of silica gel is mainly physical adsorption, which can be regenerated and used repeatedly. So what is the use of silica gel products and what fields it is applicable to? OYIGIFTS will answer the following questions

Silica gel, also known as silicate gel, is a highly active adsorbent material, which is amorphous. Silicone has many advantages over other similar materials, such as high adsorption performance, chemical stability (does not react with any substance except strong bases and acids), good thermal stability, and high mechanical strength.

Silica gel can be divided into two categories according to its nature and composition: organic silica gel and inorganic silica gel. Organic silica gel is mainly used in aviation, cutting-edge technology, military technology sectors of special materials and construction, electrical and electronic, automotive, machinery, chemical light industry, medicine, and medical treatment, etc.; inorganic silica gel is mainly used in desiccant, catalyst carrier, matting agent, toothpaste abrasive, etc. The toughness and elasticity of silicone products are very good, and will not be deformed by external forces, and are non-toxic, tasteless, and colorless, no harm to the human body.

Features of silicone products.

(1) High and low-temperature resistance: they can be used for a long time at 200℃ and still have elasticity at -60℃.

(2) Electrical insulation properties: The dielectric properties of silicone rubber are excellent, especially at high temperatures, which greatly exceed those of general organic rubber, and the dielectric strength is almost unaffected by temperatures in the range of 20-200°C.

(3) Excellent weathering resistance, ozone resistance, and ultraviolet radiation resistance.

(4) Excellent high-temperature compression permanent deformation.

(5) Good processing performance, easy molding, and other advantages can be extruded by hot air vulcanization molding, die-plus molding, extended molding, and other methods to make

Silicone products are mainly used in the following places.

1、Silicone products are indispensable components for making copiers, keyboards, electronic dictionaries, remote controls, toys, silicone keys, etc.

2、It can be used to make durable shaped molding gaskets, encapsulation materials for electronic parts, and maintenance materials for automotive electronic parts.

3、It can be used to make electronic components, and molded high-point pressure edge sub.

4、It can be used in the production of kitchen products, kitchenware, and related auxiliary kitchenware products.

5、Can be used for medical equipment accessories, because silica gel is colorless, tasteless, non-toxic, and other characteristics widely used in the medical industry.

6、It can be used to make conductive silica gel, medical silica gel, foam silica gel, mold-making silica gel, etc.

7、It can be used in the construction and repair of houses, sealing of high-speed kilometer joints, sealing of bridges, and other sealing projects.

8、It can be used for baby products, mother and baby products, baby bottles, and bottle protectors.

Silicone products due to the superior performance of silicone material, coupled with silicone is non-petroleum products, do not rely on increasingly scarce oil resources, making silicone products become a substitute for similar plastic products has long become inevitable; at the same time, silicone products can be applied to a lot of plastic products can not do the field, such as baby pacifiers, human organs, etc., the application prospects are very broad.